Electrostatic Chuck Multi-Zone Pressure Independent Power Supply

The manufacturing of advanced semiconductor devices, particularly at the leading-edge nodes, demands unprecedented levels of process uniformity across 300mm and larger diameter wafers. Plasma etching and chemical vapor deposition processes are critically sensitive to localized temperature variations, which are directly influenced by the heat transfer efficiency between the wafer and the chuck. Traditional single-zone electrostatic chucks (ESCs) provide a uniform clamping force, but they cannot compensate for inherent process non-uniformities, such as edge effects in plasma density or gas flow, which create radial temperature gradients. This has driven the development of multi-zone electrostatic chucks, where the clamping electrode is segmented into independently controllable concentric zones. The power supply system that drives these zones is not merely a high-voltage source; it is a sophisticated, multi-channel control system responsible for managing wafer flatness, heat transfer, and ultimately, within-wafer critical dimension uniformity.

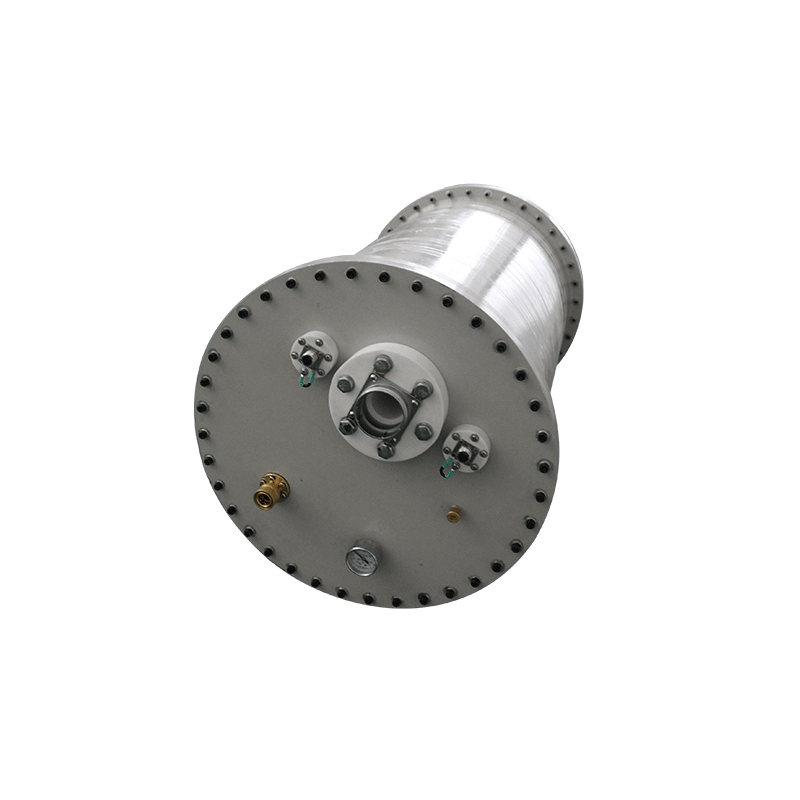

The primary function of an ESC is to generate a strong electrostatic force, typically via the Johnsen-Rahbek (JR) effect for semiconductor-grade chucks, which requires the application of a high DC voltage, often in the range of +/–1500V to +/–3000V. In a multi-zone configuration, each zone—commonly three to six concentric rings—requires its own isolated high-voltage output. The key challenge is not just generating multiple high voltages, but ensuring they are independently and precisely controllable while maintaining complete electrical isolation between zones to prevent interference and arcing. This independence is crucial for "pressure tuning." By applying a slightly different voltage to the edge zone versus the center zone, the operator can subtly modulate the local clamping pressure. Since the thermal contact conductance between the wafer backside and the chuck surface is a strong function of this interfacial pressure, independent voltage control translates into independent control of local heat transfer coefficients. This allows for real-time correction of radial temperature profiles, flattening the wafer's thermal map during processing.

The design of such a multi-zone power supply is an exercise in precision, isolation, and integration. Each output channel must feature its own fully isolated DC-DC converter, feedback loop, and monitoring circuitry. The isolation barrier between any two channels must withstand the full inter-zone potential difference, which could be several kilovolts, plus a significant safety margin. This is typically achieved through the use of individual isolation transformers or dedicated, high-isolation-voltage DC-DC converter modules for each channel. Cross-talk between channels must be minimized to the ppm level; a fluctuation in the current demand of the outer zone due to plasma interaction should not cause a ripple on the center zone's voltage, as this would introduce unwanted thermal noise.

Control dynamics are equally important. Advanced process controllers use input from in-situ temperature sensors, such as thermal couples or emissivity-independent pyrometers embedded in each chuck zone, to calculate the required thermal tuning. This controller sends setpoint commands to the multi-zone power supply, which must adjust its individual output voltages with high resolution (often millivolt precision on a kilovolt scale) and adequate bandwidth. While the thermal time constants of the wafer-chuck system are relatively slow (seconds), the power supply's control loop must be stable and free of overshoot to avoid creating thermal oscillations. Furthermore, the supply must manage complex sequencing during wafer handling: ramping up all zones simultaneously to achieve initial flat clamping, then transitioning to the fine-tuned "process voltage" profile, and finally executing a rapid and reliable de-chucking sequence, which often involves an active AC voltage discharge cycle to neutralize residual charge.

Integration with the tool's safety interlock system is non-negotiable. The supply must continuously monitor for faults such as arc detection within any zone (indicative of wafer breakage or contamination), excessive leakage current (suggesting surface degradation or coolant intrusion), or loss of a zone. Upon any fault, it must safely and sequentially shut down all outputs and communicate the precise fault condition to the main equipment controller. The evolution of this technology is pushing towards even finer zoning and the integration of RF bias sensing into the clamping control loop, as the local plasma potential also affects the effective clamping field. Therefore, the multi-zone ESC power supply has evolved from a simple clamp generator into a critical process uniformity actuator, where its multi-channel stability and independent programmability directly enable the angstrom-level uniformity required for volume production of next-generation integrated circuits.