Domestic Substitution and Innovative Solutions for Annealing Machine Power Supplies

The push toward domestic substitution of annealing machine power supplies has accelerated in recent years, driven by supply chain resilience requirements and the need to reduce dependency on imported high-voltage conversion technologies. Rather than merely replicating established foreign designs, domestic engineering teams have focused on architectural innovations that leverage locally available semiconductor materials, manufacturing capabilities, and a deeper understanding of specific application demands within the national metals processing sector.

A core innovation lies in the development of hybrid cascaded converter topologies that combine medium-frequency transformer isolation with series-connected low-voltage IGBT modules on the primary side and high-voltage diode rectification on the secondary. This approach circumvents the historical difficulty of obtaining reliable high-voltage high-current IGBTs or IGCTs domestically by distributing voltage stress across multiple lower-rated devices while maintaining excellent dynamic performance. The resulting systems achieve voltage ratings exceeding 20 kV with switching frequencies above 10 kHz, enabling compact magnetics and significantly reduced acoustic noise compared to traditional line-frequency transformer-rectifier sets.

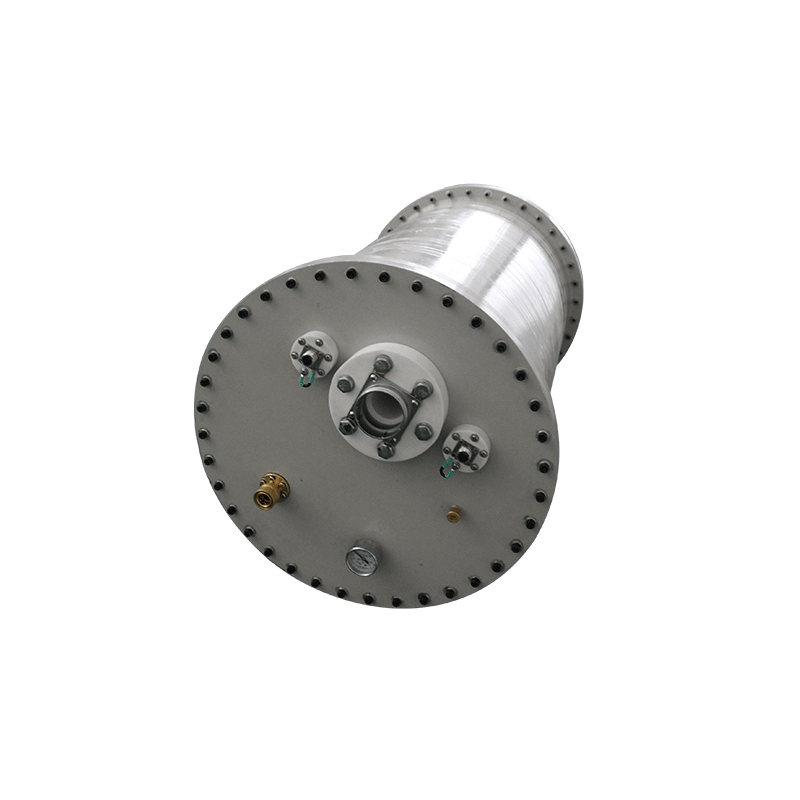

Cooling system redesign represents another area of substantial domestic advancement. Instead of relying on imported deionized water circulation units prone to leakage and corrosion issues, new designs employ immersion cooling of the power semiconductor stacks in domestically formulated fluorinated liquids that exhibit superior dielectric strength and thermal conductivity. The elimination of water-based cooling loops not only enhances long-term reliability in humid environments typical of many annealing plants but also reduces maintenance complexity and eliminates the risk of catastrophic short circuits from coolant contamination.

Control system architecture has been completely rethought around domestic 32-bit DSP and FPGA platforms. These controllers implement adaptive predictive algorithms that compensate for grid voltage fluctuations common in industrial parks, maintaining output stability within ±0.5% even during ±15% input variation. The algorithms also incorporate workpiece temperature feedback through non-contact pyrometry to modulate power in real-time, achieving energy delivery precision previously attainable only with much more expensive imported closed-loop systems.

Significant effort has been devoted to electromagnetic compatibility and harmonic mitigation without dependence on imported active front-end technology. Novel passive filter designs using domestically produced nanocrystalline cores achieve total harmonic distortion below 5% across the entire load range while maintaining power factors above 0.97. These filters are integrated directly into the power module enclosure, reducing footprint and cabling complexity compared to separate filter cabinets common in older imported installations.

Standardization initiatives have produced a family of modular power bricks rated from 50 kW to 500 kW that share common control interfaces, cooling connections, and mechanical mounting. This standardization enables rapid configuration of systems from 500 kW laboratory-scale units to multi-megawatt continuous annealing lines using identical components, dramatically reducing spare parts inventory and engineering time. The modular approach also facilitates gradual replacement of imported systems in operating plants, allowing domestic content to increase progressively without full line shutdowns.

Particular attention has been paid to the unique requirements of annealing copper and aluminum alloys processed extensively within the country. Dedicated output regulation algorithms optimize current ripple characteristics to minimize surface marking on bright annealed strip while maximizing heating rate. These algorithms operate entirely within domestic controller firmware, eliminating reliance on proprietary foreign software that previously required expensive licensing and created vulnerability to export controls.

Reliability engineering has incorporated lessons from local operating conditions, including frequent cold starts in winter and high dust environments. Power semiconductor junction temperature is actively managed through dynamic derating curves that account for both ambient conditions and historical duty cycle, extending component life well beyond ratings achieved in more temperate climates. Fault diagnostic routines provide Chinese-language messaging and direct integration with domestic SCADA platforms, reducing training requirements for plant personnel.

The resulting domestically developed power systems have demonstrated mean time between failures exceeding 50,000 hours in continuous galvanizing line applications, surpassing many imported equivalents operating under similar conditions. Total cost of ownership calculations show payback periods of less than three years when replacing aging imported systems, driven by lower initial purchase price, reduced maintenance requirements, and elimination of import duties and currency risk.