450 kV Grid-Controlled High-Voltage Power Supply for Electron-Beam Melting

Electron-beam melting of reactive alloys such as titanium aluminide and nickel superalloys demands beam power control from 0.2 kW to 60 kW within 80 µs while maintaining acceleration voltage stability better than ±0.14 % at 450 kV to prevent evaporation rate fluctuations that cause inclusion defects. Grid-controlled supplies therefore combine a rigidly regulated main high-voltage deck with an ultra-fast grid modulator capable of full beam extinction in <2.8 µs.

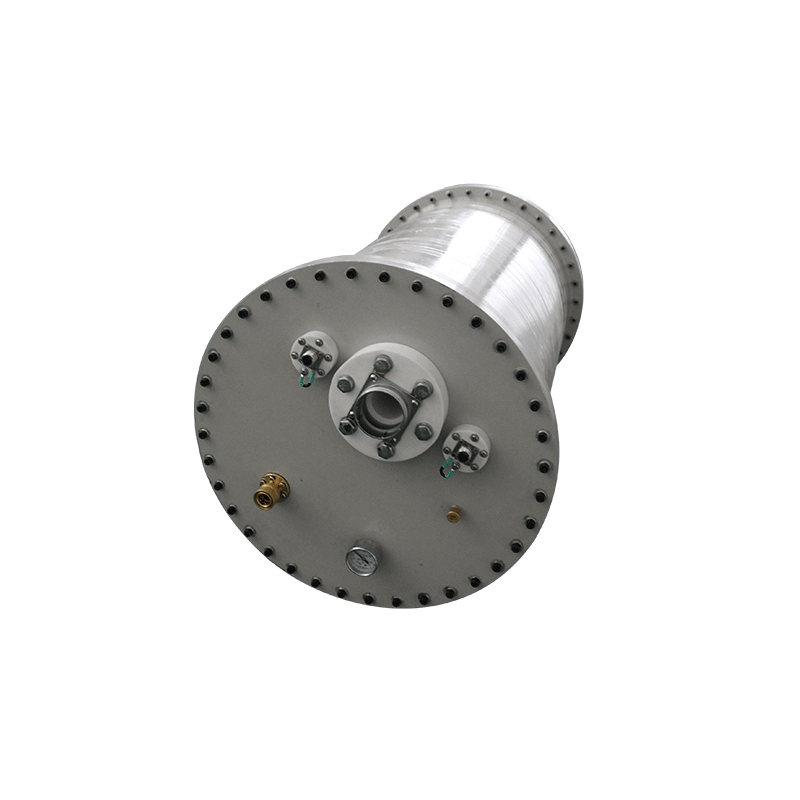

The main 450 kV deck uses a 32 kHz parallel-fed Cockcroft-Walton multiplier driven by a phase-locked resonant converter regulated to ±18 V through a high-bandwidth series linear regulator on the primary side. Stored energy is limited to 22 J by distributed oil-filled capacitors and deliberate cable selection.

Beam current is controlled by a grid electrode floating at –4.8 kV relative to the cathode, driven by a solid-state modulator consisting of 48 series-connected 1.2 kV silicon carbide MOSFETs in a Marx-like configuration. Turn-on occurs in <1.1 µs by simultaneous triggering via fiber-optic distribution; turn-off uses active gate clamping and a 1.8 kV negative extraction pulse that sweeps residual electrons in 2.4 µs total. Modulation bandwidth exceeds 180 kHz, enabling layer-to-layer power ramping and real-time melt pool stabilization via optical pyrometry feedback.

Droop compensation during high-power hatching uses a feed-forward term derived from beam current measurement at the collector: when current exceeds 110 mA, the main deck voltage is automatically raised by 280–420 V within 62 µs to counteract gun perveance shift, maintaining focal spot size within ±26 µm.

Vacuum compatibility is achieved by full encapsulation of the grid modulator in low-outgassing epoxy and remote location of the main power stage outside the chamber, with only the grid feedthrough and bias resistors inside vacuum. All control fibers are radiation-resistant pure silica with metal coating.

Defect mitigation during power transitions uses a two-stage blanking sequence: first the grid extinguishes the beam in 2.6 µs, then a mechanical shutter closes in parallel for redundant safety during long idle periods.

These grid-controlled systems routinely deliver melt rate stability supporting inclusion-free Ti-6Al-4V builds with surface finish below Ra 4.2 µm as-printed and geometric tolerance under ±38 µm on 420 mm tall aerospace structural parts.