225kV High Voltage Power Supply Fault Arc Fast Cut-off

The reliable operation of high-voltage direct current (HVDC) systems at the 225 kilovolt level represents a critical infrastructural requirement in fields ranging from high-power laboratory testing to specialized industrial processing. Within these systems, the most severe and potentially catastrophic failure mode is the formation of a sustained electrical arc. Such an event, if not interrupted within microseconds, can liberate destructive levels of energy, causing permanent damage to insulation, vaporizing conductors, and posing significant safety risks. The design and implementation of a fault arc fast cut-off system is therefore not a supplementary protection feature, but a fundamental and integrated engineering mandate. This system must function as a ultra-high-speed circuit breaker, capable of detecting the inception of an arc and completely isolating the power source before the fault current reaches its prospective peak, thereby limiting the total let-through energy (I²t) to a non-destructive level.

The challenge begins with the physics of arc formation in high-pressure gas or across solid dielectrics. The transition from an insulating state to a conductive plasma channel is not instantaneous but follows a distinct, albeit rapid, progression: initial field emission, a Townsend pre-discharge phase, streamer propagation, and finally, thermalization into a high-current arc. A truly effective fast cut-off system must intervene during the pre-arc or early streamer phase. Relying solely on the detection of overcurrent is insufficient, as by the time a conventional breaker reacts, the arc is fully established and significant energy has already been deposited. Consequently, detection must be based on the precursors to a full breakdown. Advanced monitoring employs a combination of electrical and non-electrical signatures. The rate of change of current (di/dt) is a primary electrical indicator; an arc presents a near-zero impedance, leading to an exponentially faster current rise compared to a normal load transient. Ultra-fast current transducers, such as precision Rogowski coils with nanosecond-level response, are essential for this measurement. Simultaneously, a sudden collapse in the output voltage (dv/dt) signals impedance failure. For galvanic isolation and even faster response, optical detectors are employed. These can be broadband photodiodes or specifically tuned vacuum ultraviolet (VUV) sensors that detect the intense photon emission characteristic of a developing plasma, providing a detection signal often within tens of nanoseconds, completely independent of electrical coupling.

The core of the cut-off system is the interrupting mechanism, where conventional electromechanical devices are orders of magnitude too slow. The solution lies in solid-state or hybrid switching architectures. A prevalent design uses a main conduction path composed of a series-stack of integrated gate-commutated thyristors (IGCTs) or high-voltage IGBTs. These semiconductors can be turned off via their gate signals, but the challenge is to do so while they are conducting a rapidly rising fault current. This necessitates a forced commutation circuit. Upon receipt of the arc detection signal, a pre-charged capacitor bank is switched via a low-inductance path to inject a high-amplitude reverse current pulse into the main semiconductor stack. This forces the anode current to zero, allowing the devices to regain their blocking state within 1 to 5 microseconds. Crucially, the energy and timing of this commutation pulse must be meticulously calculated to overcome the di/dt of the fault.

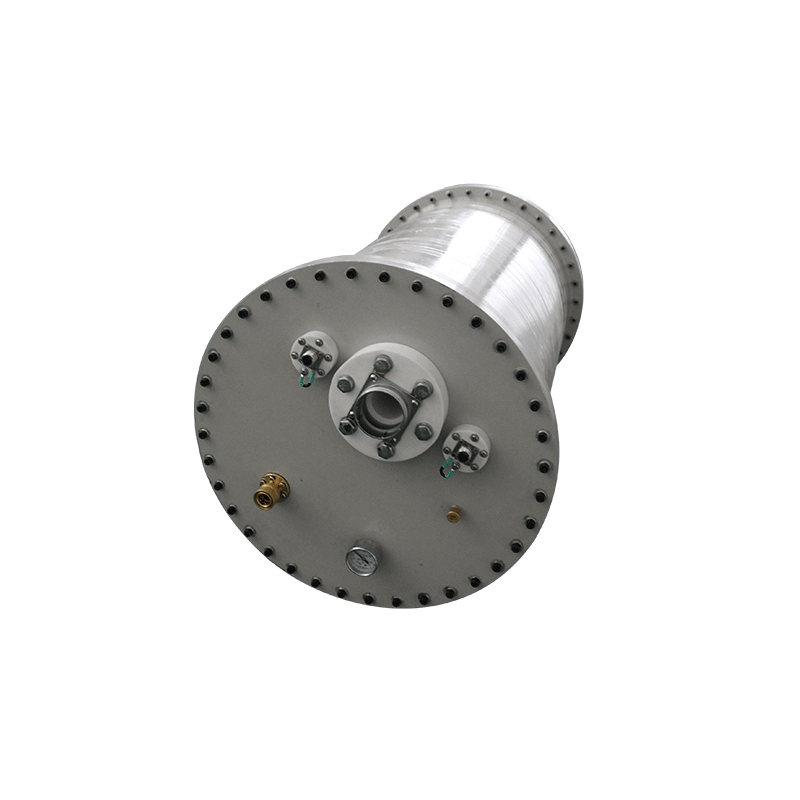

However, turning off the main switch is only half the battle. The system possesses significant magnetic energy stored in the loop inductance of cables, buswork, and the transformer. If this energy is not provided a controlled dissipation path, it will induce massive voltage spikes (L di/dt) that can destroy the semiconductors just as they turn off. Therefore, a coordinated energy diversion path is activated concurrently with commutation. This often involves a triggered spark gap or a stack of avalanche diodes that provide a low-inductance route to shunt the inductive current into a metal-oxide varistor (MOV) bank or a high-power, non-inductive absorber resistor. This component must safely dissipate the trapped magnetic energy. The high-voltage power supply itself must be designed to support this action. Its output stage should have minimal stored capacitive energy, and its control loop must be instantly disabled and its front-end input contactor opened to prevent any further energy feed.

System integration demands rigorous validation. The entire cut-off sequence—from detection through commutation to energy diversion—must be tested under realistic fault conditions, often using a deliberate test gap to initiate a controlled breakdown. The timing of each stage is calibrated to ensure the total interruption time, from arc inception to current zero, is typically less than 10 microseconds. This ensures the let-through energy remains below the withstand rating of the system's bushings, spacers, and chamber walls. Furthermore, the system must be fail-safe and include self-diagnostics. Redundant detection channels and periodic functional testing of the commutation circuit are standard practices. In essence, the 225kV fast arc cut-off system is a dedicated, ultra-fast protection layer that operates on a timescale divorced from the main power conversion processes. Its existence transforms a high-energy system from a potential hazard into a manageable, fault-tolerant tool, enabling safe operation at the extreme boundaries of electrical insulation.