Semiconductor etching machine Recommended Products

TD2200

Soft Switching ,Output Voltage 1kV-100kV ,Output Power 600W ,Digitally Programmable ...

View Products

TD2202

Output Voltage 1kv-150kV ,Output Power 2kW ,Digitally Programmable ,Nanosecond Protec...

View Products

THP2350

Output Voltage 20kV ,Output Power 5kW ,0.1% p-p ripple ,Fast recover、low arc current...

View Products

TD2318

Output voltage 1kV~120kV Ou Output voltage 1kV~120kV Output voltage 1kV~120kV ,Output p...

View Products

Semiconductor etching machine

High stability high precision low ripple and fast response speed

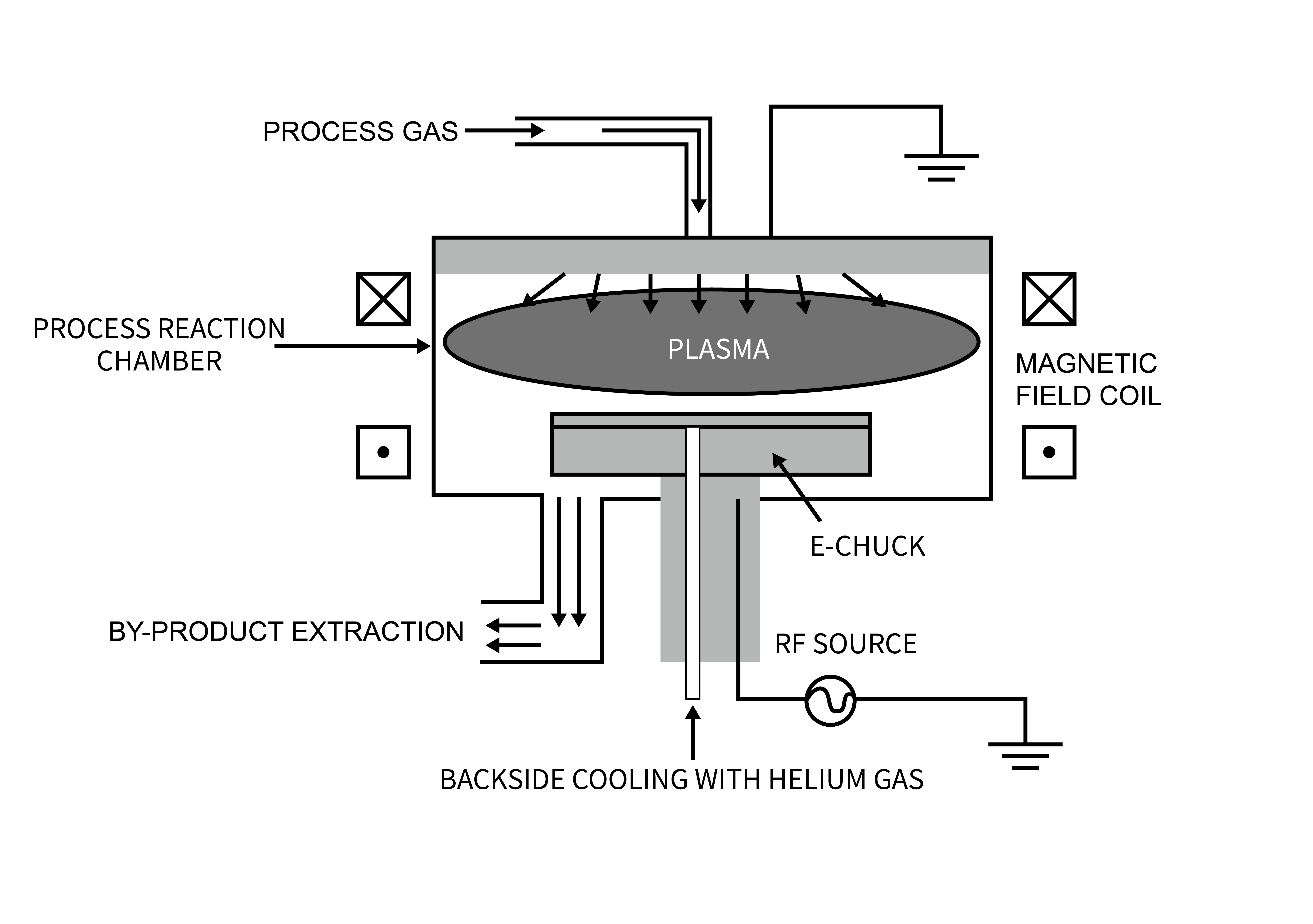

Semiconductor etching machines are one of the core process equipment in chip manufacturing (semiconductor manufacturing), and are known as the "three major components" of the front-end process along with photolithography machines and thin film deposition equipment.

Its core function can be simply understood as "the carving knife of the microscopic world". During the chip manufacturing process, after the circuit pattern is exposed onto the silicon wafer coated with photoresist by the photolithography machine, the task of the etching machine is to precisely remove the film layer that is not protected by the photoresist according to this pattern, thereby replicating the required circuit pattern on the film on the silicon wafer. Etching processes are mainly divided into two categories: wet etching and dry etching. Modern advanced chip manufacturing mainly relies on dry etching, especially plasma etching technology, which places extremely high demands on the accuracy, stability and repeatability of process control. During this process, the high-voltage power supply serves as the core power source of the etching system, and its performance directly determines the quality of plasma generation and process stability - just like the engine and transmission in a car, controlling the "power output" and "response rhythm" of the entire equipment. Our company specializes in the research and development as well as manufacturing of high-voltage power supplies. Our products feature core advantages such as high stability, high precision, low ripple, and fast response speed, making them particularly suitable for high-demand semiconductor etching scenarios