Application of Teslaman TC4160 High Voltage Power Supply in Container Sealing Integrity Test

Micro-hole leaks of microns or smaller cannot be detected by naked eyes, so it is particularly important to use appropriate methods to detect defects in pharmaceutical packaging, and high-voltage discharge leak detection is one of many detection methods.

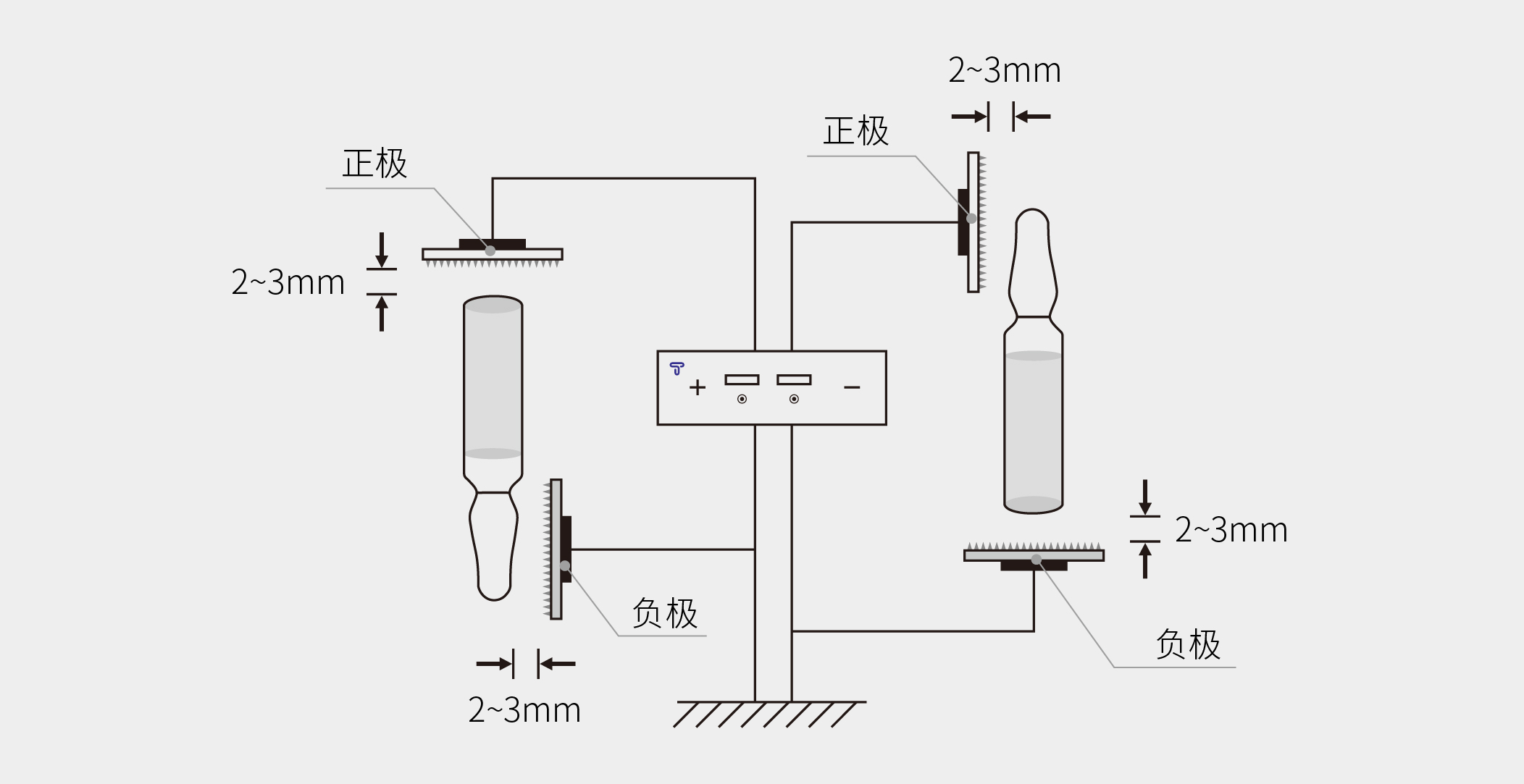

The working principle of high voltage discharge leak detection:

The commercial power is converted by the frequency conversion power supply and then boosted by the transformer. As the detection power supply, the sensor transmits the real-time detection data to the control center for signal processing and comparison, and then judges whether it is good or bad, and then controls the actuator to execute the rejection action.

The difference from the traditional leak detection method:

1. Do not destroy the packaging

During normal detection, the micro-current high-voltage discharge method can use a higher voltage than the traditional high-voltage discharge method for detection, but it can still obtain better detection sensitivity. Therefore, it can avoid the potential damage to the packaging caused by the high voltage setting. Especially for testing ampoules with weak tips.

2. Do not destroy drugs

When the same high voltage is used to detect products, the voltage generated by the micro-current high-voltage discharge method on the inner wall of the package is 1/20 of that of the traditional high-voltage discharge method, which greatly reduces the probability of the drugs in the package being damaged.

3. Reduced requirements for liquid conductivity

The traditional high-voltage discharge method requires the liquid conductivity to be greater than 5 μS/cm, while the micro-current high-voltage discharge method can detect liquids with a conductivity of 1 μS/cm, such as water for injection or water needles without obvious conductive substances (such as salts). Therefore, the micro-current high-voltage discharge method has a wider range of applications.

4. Better sensitivity

Compared with the traditional high-voltage discharge method, the sensitivity of the micro-current high-voltage discharge method is increased by more than 2 times, and the data separation is better, which can avoid false negative and false positive results caused by insufficient sensitivity.

5. Almost no ozone is generated during the detection process

Oxygen in the air is converted to ozone due to high voltage discharge exposure. The traditional high-voltage discharge method is prone to generate ozone during the detection process, usually reaching several hundreds of ppb. Due to the strong oxidizing properties of ozone, this concentration of ozone may affect the stability of the drug or deteriorate the drug.

Teslaman is a high-tech enterprise facing the frontier of military industry, scientific research and technology. Since its birth in 2005, it has provided a large number of test equipment for my country's scientific research and military industry. It is also equipped with high-voltage power products ranging from 1W2KV to 120KW450KV for some cutting-edge equipment manufacturing enterprises in my country, from semiconductor processing equipment to nanotechnology, from monitoring instruments to environmental protection equipment, from new materials to high-energy physics. From food processing to health care, we provide all kinds of special high-voltage power supply products for countless industries.