Electrostatic Spinning Recommended Products

TCM6000i

Maximum Output Voltage 30kV ,Maximum Output Power 30W ,Programmable Power Trip Featu...

View Products

TCM6002

Maximum Output Voltage 50kV, Adjustable ,Maximum Output Current 3mA ,Maximum Output ...

View Products

TD2202

Output Voltage 1kv-150kV ,Output Power 2kW ,Digitally Programmable ,Nanosecond Protec...

View Products

TLP2041

Output Voltage 1kV-225kV ,Output Power 5kW-10kW ,Digital Programmable, Nanosecond Prot...

View Products

TRC2020

Output Voltage 1kV-100kV ,Maximum Output Power 300W ,Digital Voltage and Current Dis...

View Products

TRC2025

Output Voltage 1kV-100kV ,Output Power 500W-1kW ,Over-Voltage, Over-Current, Short Cir...

View Products

Electrostatic Spinning

Stable output voltage Digital programmable Malfuction alarm Sound&Light alarm optional Nano-second response protection

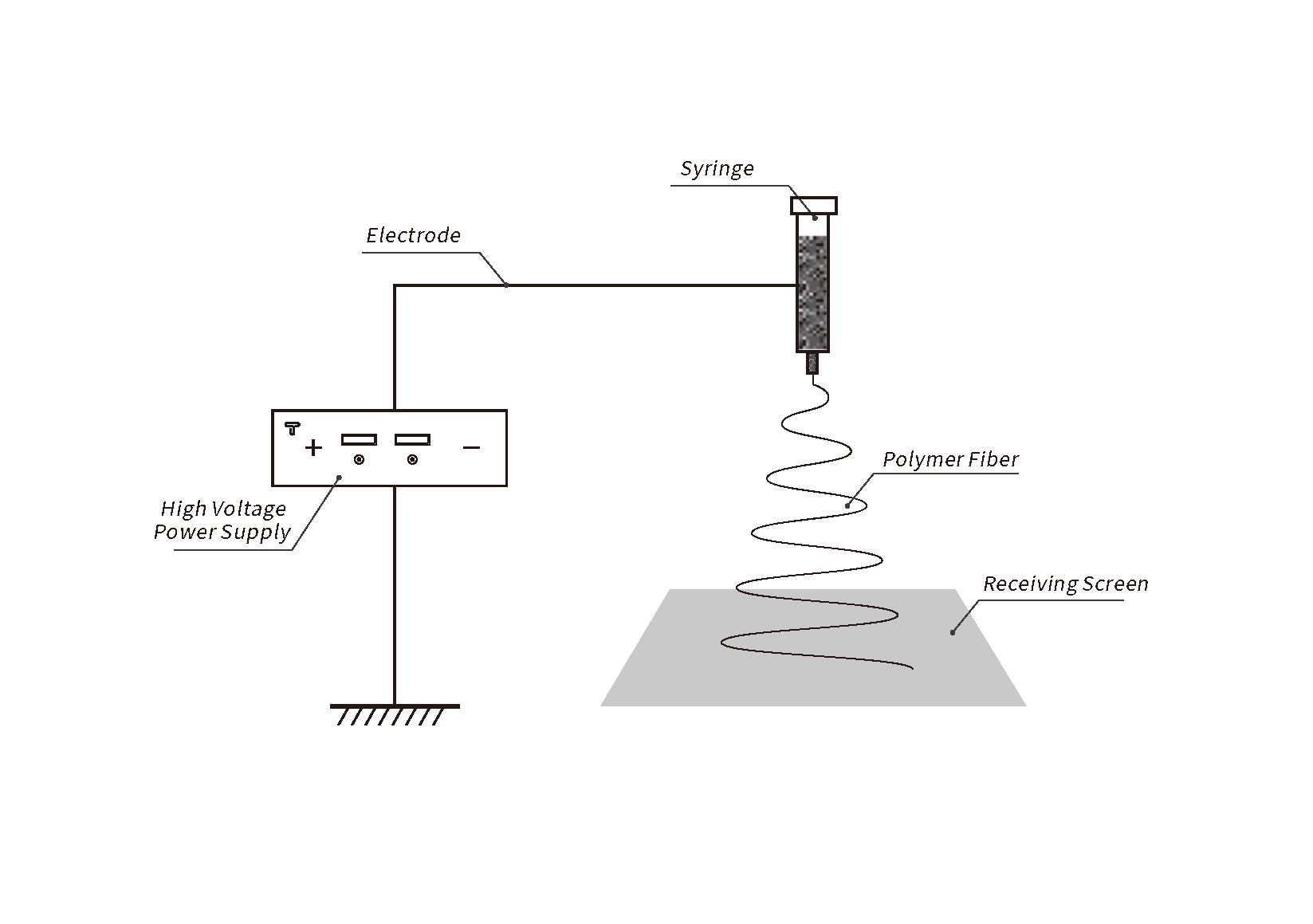

Electrospinning is a method of making fibers from polymer solutions or molten polymers using electrostatic forces. In the electrospinning, the polymer solution or molten polymer is extruded through a nozzle and then subjected to a high-voltage electric field, which induces electrostatic charges to form. Electrospinning technology can produce fibers with diameters ranging from a few micrometers to several hundred micrometers, characterized by small fiber diameter, large surface area, and high porosity.

Project Introduction

- In the new material electrostatic preparation plant, Teslaman provides a variety of power supply solutions, with thousands of units supplied. Suitable various harsh environments, including corrosive environments. Our products are known for their high stability and excellent adaptability, meeting the demands of different working occasions. These advantages Teslaman's solutions widely recognized by customers, becoming the ideal choice for the electrostatic spinning industry. We are committed to providing customers with the perfect supply configuration to help improve production efficiency and ensure the long-term stable operation of equipment